Making a homemade Mini Forge (sometimes called a firebrick forge) can be a great way to make jewelry and other objects at home, or to heat and bend small pieces of metal to make something like a knife. You can also use a Mini Forge to make and stamp coins.

How to make a Homemade Mini Forge

Project Warning: This project deals with combustibles and extreme temperatures. This Mini Forge can reach temperatures of over 2500° F (1370° C). Extreme caution should be taken and adult supervision is mandatory. Care should always be taken not to overheat the torch or forge. There is a serious risk of injury and burns if not used correctly. If you have any doubt about your ability to do this project, please do not do it.

Also, using a torch in this manner, while safe, will likely void the manufacturer’s warranty and may result in decreased life of the nozzle. You have been warned.

Download the Mini Forge Plans Here

Parts List for this Project

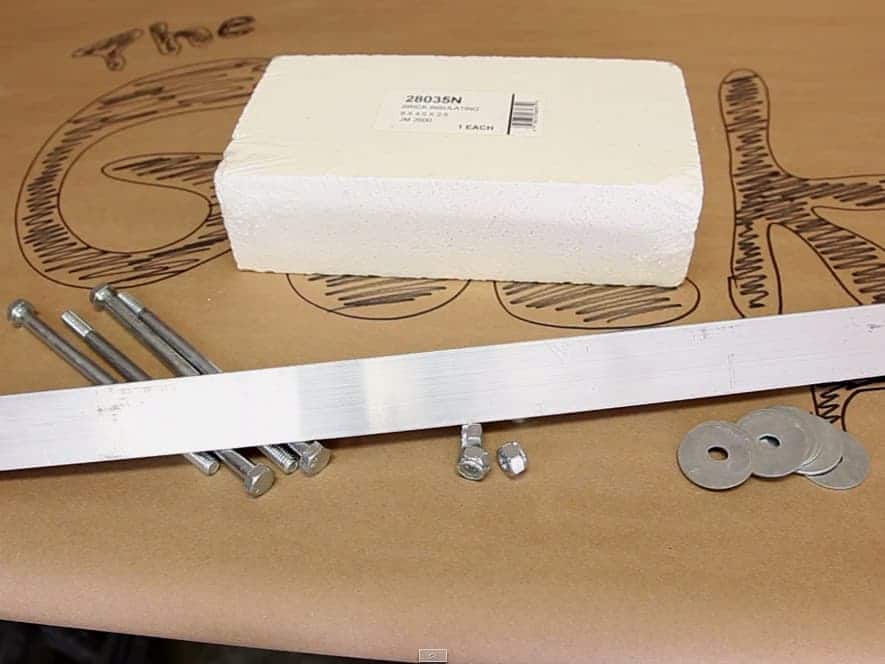

Here’s a quick parts list for this project to help you get started:

- Insulating Firebrick (9 x 4 1/2 x 2 1/2 in / 230mm X 65mm)

- MAP torch

- Hex Bolts (1/2-13″ X 6″)

- Washers (1/2″)

- Hex Nuts (1/2″-13)

- Aluminum Angle (3/4 in / 19 mm)

- Hole Saw (1 1/4 in)

Building the Homemade Mini Forge

Building the Mini Forge is quite simple and only requires a few parts. You can get them all at your local hardware store or from Amazon.com. See the PDF and Sketchup Plans for all the dimensions. You’re going to need a firebrick (this is not a regular clay brick), a torch with locking trigger and tank, a two foot section of aluminum angle, and four 6 inch bolts, with nuts and washers.

When purchasing the firebrick, make sure it is rated to at least 2600° F (most are) as we’re going to generate a lot of heat. Using an under-rated block will cause fracturing that could lead to burns and/or starting a shop fire.

The first step is to cut the firebrick into two equal halves. This can be done in any number of ways. I chose to use my compound miter saw because it makes for a very clean finish.. If you don’t have one of those you can use a hacksaw, a bandsaw, or drywall saw.

The firebrick is made out of ceramic and silica so it won’t damage your blade and will cut easier than most softwoods (regular bricks are made out of sand and clay). Just don’t cut it too fast or you could fracture the brick. It’s actually somewhat fragile and too much pressure can be bad news for your Mini Forge (the speed in the video is actual speed, not sped up or slowed down).

Step two is to drill the holes in the forge. I used a 2 inch hole saw bit and my drill press. Again, I did this because I felt like it made the cleanest cut. You could also use a paddle bit and a handsaw if that’s all you have.

Be sure to put a sacrificial board under the brick so that you don’t get a bunch of “blow out” when the bit exits the backside of the brick. This is especially import if you use a paddle bit.

You’re going to need a hole that is the same size as the nozzle of your torch in the side of the brick. That hole of course intersects with the larger one in its center. The exact dimensions are in the PDF and Sketchup plan files.

Step three is to make the angle brackets. I used aluminum because it is lightweight and has a little give to it which helps with the softness of the firebrick, but you could use steel if that’s what you already have, but do not use wood or plastic! Cut the section of 24 inch angle into four 6 inch sections. You can do this with a cut-off wheel, metal cutting rotary saw, handheld hacksaw, or a reciprocating saw (sawzall).

Drill a hole at both ends of each of the angle sections (on the same face) using a drill-bit that matches the diameter of the 6 inch bolts that you purchased. It’s important that these are centered so that they spread the clamping force evenly.

Assembling the Mini Forge

Assembling the Mini Forge is incredibly simple. On a flat surface place both halves of the firebrick together. Then just lay the six inch sections of angle on the two halves of the firebrick, slide the bolts through and tighten them up snugly. Again, be very careful not to over-tighten the bolts as the brick will fracture if you do.

Take care to make sure the hole for your torch is on the left or the right side of the completed firebrick. Which side is up to your preference, but if it winds up on the top or the bottom you’ll have to take it all apart.

Using the Mini Forge

The Mini Forge can be quite the cool tool around your shop, and its certain to attract questions from your friends and family who see it. It’s always a neat discussion piece around my shop.

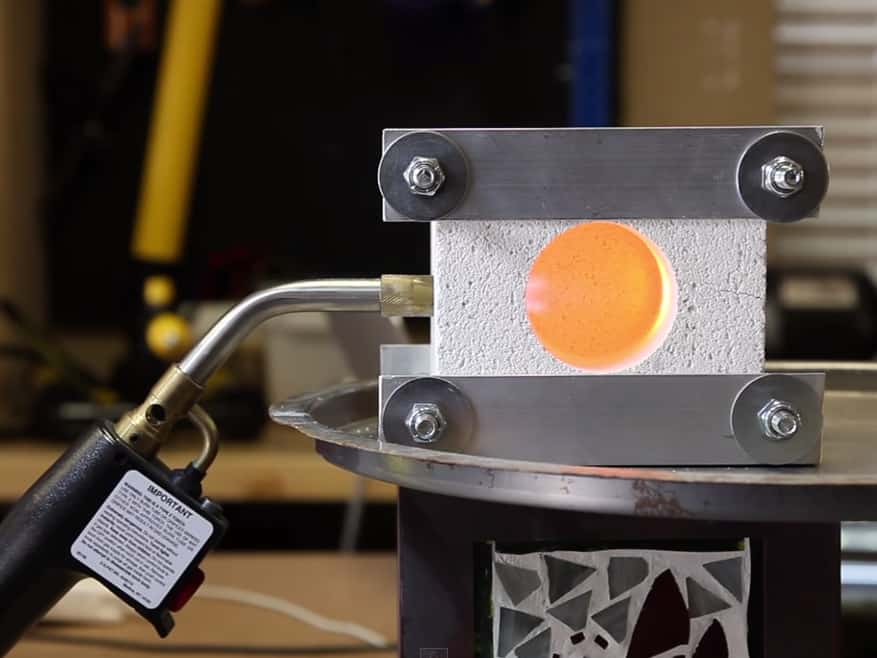

Using the Mini Forge is as simple as placing the nozzle of your torch into the small inlet hole and firing it up. It only takes a few seconds for the inside of the forge to reach operating temperature (in the video I say “minutes”, but I meant seconds).

I highly recommend you get some long handle pliers to hold your objects with so that you can keep your fingers and clothing far away from the Mini Forge. I use some 12 inch needle nose pliers I got from Amazon for $5. Don’t spend a lot of money because you’ll likely destroy them pretty quickly heating items up with them at some point anyway.

If you make the Mini Forge be sure to send me some pictures of it!

Download the Mini Forge Plans Here

The post How to make a homemade Mini Forge appeared first on The Geek Pub.